The first thing we have to do is jack up the car good and high and get jack stands under it. Then .. Remove the wheel and reposition the jack under your spring. Lift the spring with the jack .. compress it a little bit .. to where you know you are supporting it.

Next we have to remove the disc brake caliper. Just remove the two bolts in the back that I am pointing to. Note that the two bolt heads you see in the front are not the bolts. I actually have my fingers on the bolt heads.

Then hang the caliper up somehow so that it's not putting pressure on the brake hose.

Now its time to remove the hub/rotor. Remove the dust cap with a pair of channel locks .. just grab it and wiggle it off. Or pry it out with a screwdriver. It's just pushed in there. Remove the cotter pin, then the nut. Then, just pull the hub right off. It should come off easy.

Unbolt the one and only remaining bolt in the disc dust cover. The other two holes were for the disc brake caliper

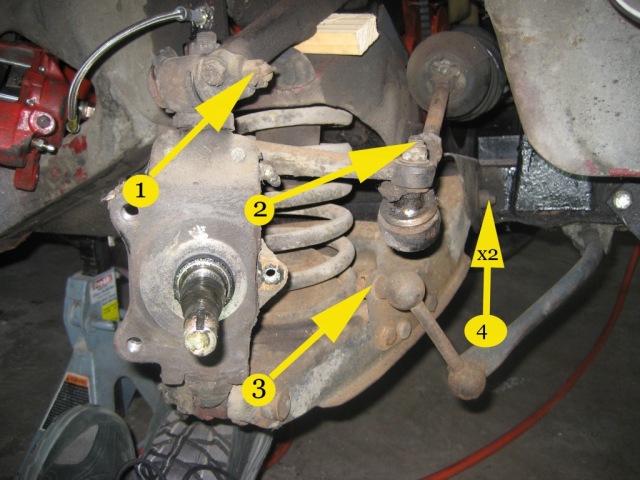

Now we get to the meat. Here is a preview of what has to be done. There are five attachment points we have to disconnect to remove the suspension.

1. Shock arm has to be disconnected from the trunnion.

2 Tie rod has to be disconnected from the steering knuckle arm

3. Sway bar has to be disconnected from the Wishbone / lower link

4. BOTH inner fulcrum pins have to be popped out.

After taking out the locking bolt ( red arrow ) .. you can take the cotter pin and nut off of the trunnion pin ( yellow arrow ) and hammer it out. If you have trouble, you may want to try and adjust your jack to vary the pressure on it. Note the orientation of the trunnion. The fulcrum pin is on this side of the kingpin, the outside.

Now that we have the trunnion apart .. We have to pop the tie rod out of the steering knuckle arm. If you don't have a ball joint / tie rod seperator, go to any auto parts store and buy one. They are really cheap .. like 10 bucks. And you will save yourself a LOT of trouble

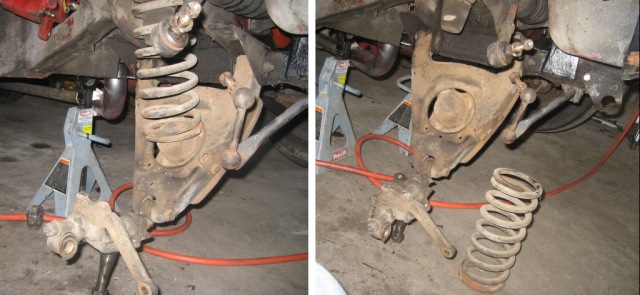

After we have the trunnion and tie rod disconnected ... It's time to unbolt the sway bar from the lower link / wishbone. When done it will look like this. Now all we have to do is lower the jack and let the wishbone / lower link swing down.

This is why you needed your car good and high. Lower the jack and the lower link / wishbone will just swing down .. pivoting on the remaining inner fulcrum pins. After it is lowered down .. you can easily pry-kick the spring out. Some may consider this unsafe. But .. at this point the pressure is so little that it just kind of falls out .. it doesn't shoot across the room. And this is on a RB midget. If you would like to use some kind of spring compressor ... go for it. This way is just way faster

Right here are the bad boy inner fulcrum pins. There are a zillion posts asking how to get these out. I can't say there is any secret ... just take the nut off and hammer the bolt(pin) out. Many people have just cut these things off with a saws-all. I had trouble getting at the one side on mine because of the exhaust so I put a torch to it and almost set my car on fire. I was able to poke the other side right out. Take note that moving the wishbone up and down may change the pressure on these and make it easier. After you get these out .. the whole assembly will drop to the floor, ready to take to the bench.

The suspension on my 76 midget was shot. I delayed doing this job for several years because I wasn't sure I could do it. Everything I read about it left questions. And there was varying vocabulary for some of the parts. Well .. I gave it a go and tried to document it as much as possible. Because I didn't really follow the instructions in the manual, there is a good chance that I did it differently than others.

I know some of this info is so basic that its almost insulting .. but .. I included it for the people who really like a hand holding. Like me. And please note that I made a common mistake during reassembly and installed my trunnions on backward .. so read everything carefully so you don't do the same thing.

If you are thinking about doing this job, it would be a good idea to hit all the bolts with penetrating oil in the days preceeding the job. According to some tests I have read, the very best penetrating oil is a 50/50 mix of ATF & Acetone.

Anyways .. here is how I did it.

.